At Bedding Boxes Direct, we build heavy-duty bedding boxes engineered for real-world performance. Our designs combine maximum strength, long service life, and custom fabrication options tailored to your operation. Whether you need a single box or a full fleet order, we deliver precision-built boxes that hold up under the toughest conditions, every time.

We’re chosen by contractors, municipalities, and equipment dealers because we provide:

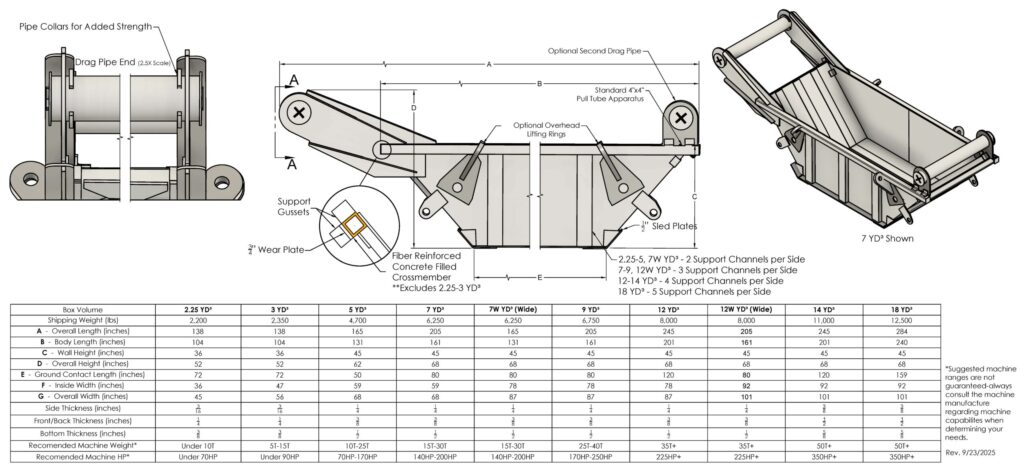

Custom fabrication from 2.25 to 18+ cubic yards

Heavy-duty reinforcements including gussets, sled plates, and concrete-filled crossmembers

Fast lead times and bulk order pricing

Custom-painted colors to match your fleet or company branding

Quantity: We support large-volume production runs with consistent quality and cost efficiency

Nationwide shipping

Our boxes are trusted in:

Utility trenching and backfill

Sewer and water main installation

Road and site preparation

Aggregate handling and storage

Each unit is tested for strength, balance, and ground performance, giving crews faster cycle times and reduced material loss.

We fabricate boxes in multiple capacities to suit any job or machine range:

| Box Volume | Machine Weight Range | Machine Horsepower |

|---|---|---|

| 2.25–3 YD³ | Under 10–15T | Under 70–90 HP |

| 5–7 YD³ | 10–30T | 70–200 HP |

| 9–12 YD³ | 25–40T+ | 170–225 HP+ |

| 14–18 YD³ | 35–50T+ | 350 HP+ |

Built-in efficiency: Ground contact lengths up to 159 inches, wall heights up to 45 inches, and optimized drag geometry ensure smooth material flow and reduced machine wear.

Each bedding box from Bedding Boxes Direct is designed to outperform standard boxes in both durability and load control.

Key construction features include:

Pipe collars for added strength at drag pipe ends

Support gussets and fiber-reinforced, concrete-filled crossmembers (on 5-yard and larger models)

¾-inch wear plates and ½-inch sled plates for superior abrasion resistance

Standard 4″ x 4″ pull tube apparatus for secure machine connection

Optional second drag pipe and overhead lifting rings for transport versatility

Support channels per side scaled to box size for balanced strength and drag efficiency

Every component is precision-cut and welded to ensure structural integrity and optimal balance under load.

Monday through Friday we will respond within 24hrs. Our standard service hours are 9am-5pm (EST).

Competitively priced and made here in America with thicker gauge American steel!

Office Hours:

Mon-Fri 5AM to 5PM (MST)

Mon-Fri 7AM to 7PM (EST)